What are Shielded Cables: Construction, Uses, Types, and More

Buzzing signals, glitchy data, mysterious interference, do these sound familiar? If your cables are picking up more noise than they should, it's time to talk solutions. Enter the world of shielded electrical cables. In this guide, we’ll unpack all you need to know about shielded cables, including the types of shielded cables, their common uses, and why choosing the shielded signal cable makes all the difference for your needs.

What is a Shielded Cable?

Shielding is classified into active and passive types. Active shielding blocks noise from radiating outward, while passive shielding protects sensitive equipment from external interference. The shielding layer, usually made of thin non-magnetic materials like copper braid or aluminum foil, works mainly through grounding rather than the metal’s reflection or absorption properties. It serves as the key defense against EMI and RFI.

A typical shielded cable is built with four essential layers: a core conductor that carries the signal, a dielectric insulation layer, a shielding layer, and an outer jacket. This structure keeps signals clean, reduces noise, and ensures stable communication, especially for sensitive or high-speed data.

An advanced shielded cable, however, takes protection a step further. It features enhanced insulation and a grounding wire, wrapped in an outer jacket made of advanced TPE. This provides superior flexibility, heat resistance, oil resistance, and abrasion durability, making it ideal for demanding environments.

How Does a Shielded Cable Work?

The magic behind shielded cables lies in something called a Faraday cage. That’s just a fancy name for a conductive barrier that blocks electromagnetic fields. In a shielded cable, the metal shield wraps around the inner wires, forming a protective barrier against external interference. When outside interference hits the shield, it either reflects the energy or safely channels it to the ground.

This is why proper grounding is a big deal. If the shield isn’t grounded correctly, it can’t do its job. Typically, grounding is done at one end of the cable to avoid what's called a ground loop, a situation where the cable picks up noise instead of blocking it because of different voltage levels at each end. In some cases, like with very long cables, it's better to ground only one end to avoid issues caused by those voltage differences.

Also worth mentioning: drain wires. These are often added alongside foil shields to help with grounding, since foil on its own is hard to connect. The drain wire touches the foil and makes it easier to terminate and ground, ensuring the shield works effectively.

How to Know If a Cable Is Shielded?

Not sure if your cable is shielded? Here's a quick trick: check the markings on the jacket. Labels like F/UTP, S/FTP, or STP usually mean it’s shielded. (We will decode these later.) If you are still not sure, carefully peel back the outer layer. If you see foil, braided metal, or a bare wire running alongside the core (called a drain wire), then yes, you’ve got a shielded cable.

Why Should You Use Shielded Cables?

Like we said before, the main job of shielding is to block out unwanted EMI and RFI. EMI typically comes from electrical sources, for example, motors, relays, transformers, power lines, and fluorescent lighting. On the other hand, RFI is produced by wireless signals, such as radio transmitters, mobile phones, Wi-Fi routers, radar systems, and broadcasting towers.

In today’s world, where nearly every device relies on clean, fast, and uninterrupted data flow, even a small amount of interference or false signals can cause major headaches. Without shielding, these external noise sources can sneak into your signal lines, leading to flickering monitors, glitchy audio, frozen video calls, or unpredictable equipment behavior.

But protection from interference is just the beginning. There are several other good reasons to aim for shielded cables.

Preventing Signal Degradation and Data Loss

Unprotected cables can pick up interference that causes packet loss, delays, or complete signal corruption. Shielded cables act as a Faraday cage, reflecting and grounding electromagnetic energy, ensuring that your data, whether video, audio, or digital files, travels intact and at full speed. This is especially important in high-speed applications like Gigabit Ethernet, real-time video conferencing, or process automation systems.

Maintaining Signal Integrity in Sensitive Applications

In systems transmitting low-voltage or high-frequency signals, even minor interference can severely distort the output. This is especially critical in medical equipment, aerospace systems, lab instrumentation, and communication networks. Shielded cables ensure signal fidelity by preventing fluctuations, jitter, or harmonic distortion that could compromise sensitive measurements or controls.

Containing Internal Signal Radiation

Cables don’t just receive interference; they can emit it too. In tightly packed control panels or near sensitive components, cables without shielding can introduce interference into surrounding electronics. Shielding helps contain any electromagnetic energy generated within the cable, preventing it from radiating outward and affecting nearby systems.

Reducing Crosstalk and ANEXT

Crosstalk is the interference caused by signals bleeding between adjacent wires, which becomes a real concern in high-density environments like server racks or structured cabling systems. Shielded cables reduce both near-end and alien crosstalk (ANEXT), especially in twisted-pair data cables, ensuring that each channel remains isolated and clean, even at high transmission speeds.

Durability and Environmental Protection

Shielded cables often use more robust construction materials, offering resistance to moisture, chemicals, UV radiation, abrasion, and even rodents. This makes them ideal for outdoor installations, aerial runs, and hazardous environments where cable integrity must be preserved over time. In some applications, they also help mitigate electrostatic discharge (ESD), especially when paired with surge protection devices.

Shielded vs Unshielded Cables

Shielded and unshielded cables serve different purposes depending on the environment and the level of interference present. Since we have mentioned the reasons to use shielded cables, let’s take a look at the unshielded ones.

Unshielded cables don’t include a shielding layer. Instead, they rely on twisted pair construction to reduce some level of interference. These cables are lighter, more flexible, cheaper, and easier to work with, which makes them popular in low-interference environments like residential spaces, schools, and small offices. They don’t need grounding and can still deliver fast data speeds, but they’re far more vulnerable to interference and signal degradation when used near power lines or noisy electronics.

In contrast, shielded cables offer stronger physical protection and tend to perform better in higher temperatures. However, they are generally bulkier, more expensive, and less flexible, and require careful grounding and installation to work properly.

As a rule of thumb, when choosing or designing a cable, opt for shielded ones if you're working in a noisy environment or near devices that emit a lot of EMI. They're also the better option for long cable runs, outdoor use, or applications where performance and signal clarity are mission-critical. On the other hand, go with unshielded cables in clean, interference-free areas where flexibility, simplicity, and cost-efficiency matter more than maximum protection.

|

Feature |

Shielded Cable |

Unshielded Cable |

|

Structure |

Includes a shielding layer (foil or braided mesh) around conductors |

No shielding layer; relies on twisted pair design |

|

Interference Protection |

Excellent protection against EMI and crosstalk |

Limited protection; suitable for low-interference environments |

|

Flexibility |

Less flexible due to shielding |

More flexible and easier to install |

|

Weight |

Heavier |

Lighter |

|

Cost |

More expensive |

More cost-effective |

|

Installation |

Requires grounding and careful handling |

Simple installation; no grounding needed |

|

Durability |

Higher physical protection |

Lower physical protection |

|

Performance Stability |

More stable signal over long distances or near noisy equipment |

May experience signal degradation in high-EMI areas |

|

Typical Environments |

Industrial facilities, factories, outdoor applications, or near heavy machinery |

Homes, schools, offices, or low-EMI indoor environments |

|

Best For |

Long runs, EMI-heavy or mission-critical applications |

Short runs, flexible layouts, and cost-conscious projects |

Types of Cable Shielding Configurations

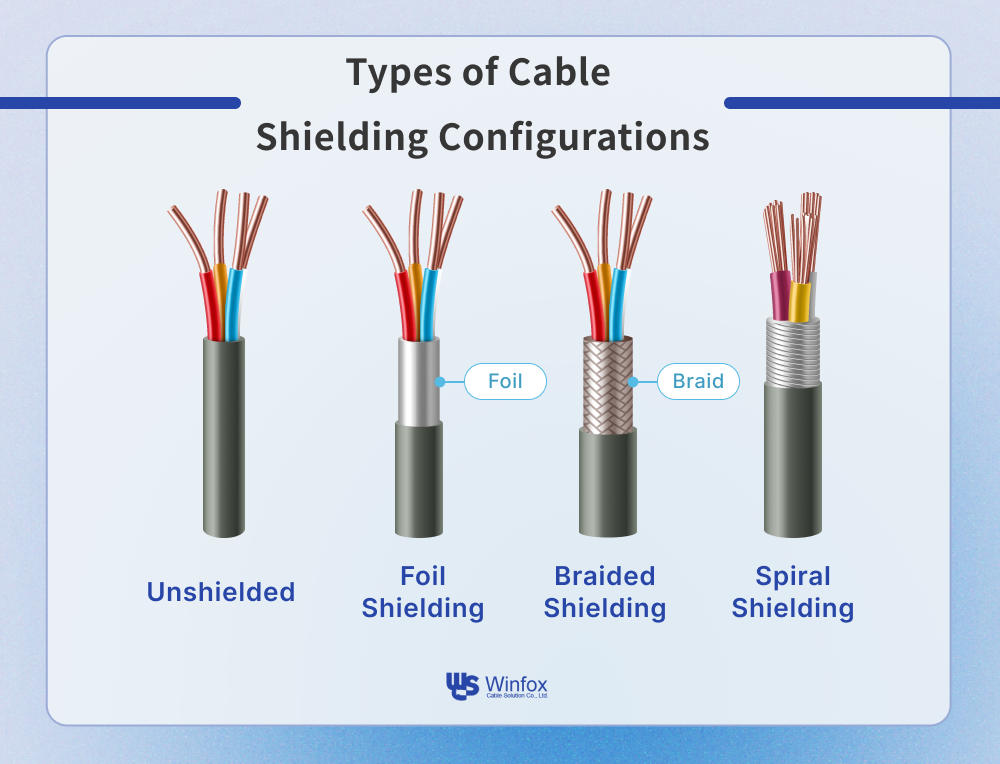

Choosing the right types of cable shielding isn’t just about preventing interference. It’s about matching your cable’s performance to your environment and signal requirements. The four most common types of shielded twisted pair cables used in multi-conductor or low-voltage signal cables are braided, foil, spiral, and combination shielding. Each type has its own structure, performance range, and ideal use cases. Let’s explore them in depth.

Braided Shielding

A mesh made from thin strands of conductive wire (commonly bare or tinned copper) woven in a crisscross pattern around the cable core. Other materials, including aluminum or stainless steel, are used as well.

Key Properties:

-

Coverage: 70% to 95% (denser weaves offer better coverage, though not full)

-

Flexibility: Good—ideal for applications with moderate movement or vibration

-

Flex Life: Good—can withstand repeated flexing

-

Frequency Range: Excellent at low to mid frequencies (up to ~100 MHz), effective at reducing low-frequency EMI due to its low resistance

-

Termination: Easier than foil; can be soldered or crimped, often terminated with or without a drain wire

Braided shielding is like the bodyguard of the cable world, for it is tough, dependable, and always on duty. It offers rock-solid protection against physical damage like cuts and crushing, and it doesn’t flinch when the cable gets bent or twisted. With its low resistance and tight weave, it’s a champ at blocking low-frequency noise, making it a favorite in audio/video setups, studio gear, and control systems where clean signals matter most.

But even the best bodyguards have their drawbacks. Braided shielding adds bulk and weight, making the cable a bit of a heavyweight. Its woven design, while strong, can let some high-frequency noise sneak through the gaps. And it’s not the most budget-friendly option on the shelf. Still, when you need rugged durability and reliable low-frequency shielding, braided shielding steps up and delivers like a pro.

Foil Shielding

A thin metallic foil (usually aluminum) wrapped helically around the cable core, often with a polyester or polypropylene backing for mechanical strength. Copper foil may be used for higher-end applications.

Key Properties:

-

Coverage: 100%—surrounds the conductors, leaving no gaps

-

Flexibility: Poor—foil is stiff and can tear if bent repeatedly

-

Flex Life: Poor—not suited for applications with continuous movement

-

Frequency Range: Excellent at high frequencies (above 100 MHz), especially for blocking RFI

-

Termination: Difficult without a drain wire, which provides a path to ground and simplifies connection

Foil shielding is the sleek, stealthy specialist of the cable world, lightweight, efficient, and perfect for high-frequency missions. It shines in high-speed data cables like Ethernet and HDMI, as well as communication and instrumentation systems where RFI runs high and complete shielding is a must. Its thin, flexible design makes it a great fit for compact spaces and tightly packed installations, delivering strong protection without bulking up the cable.

But while foil shielding is great at blocking high-frequency noise, it has its weaknesses. It's not built for battle since it offers poor mechanical durability and doesn’t hold up well in rough or highly mobile environments. It's best kept for static or semi-static applications where the cable won’t be twisted or flexed too often. Plus, it can be tricky to terminate directly, often requiring extra care or additional materials.

Spiral Shielding

Single or multiple strands of copper wire helically wrapped around the cable core. This type is not woven, making it more flexible than a braid.

Key Properties:

-

Coverage: Typically 90–95%, but the spiral may open when bent, reducing effectiveness

-

Flexibility: Excellent—ideal for retractable cables or frequent movement

-

Flex Life: Poor—coils can deform under repeated stress

-

Frequency Range: Effective at low frequencies (below ~1 MHz); not suitable for high-frequency applications due to inductance and high resistance

-

Termination: Mixed reports; some say it’s easy, others find it more difficult, depending on cable design

Spiral shielding is the agile acrobat of the shielding world as it is light on its feet, super flexible, and built to move. It’s the go-to choice for audio cables, musical instruments, and handheld or mobile gear that needs to bend, twist, and flex without missing a beat. Its spiral-wrapped design offers excellent shield integrity in applications with constant motion, especially where torsional movement is a factor.

But with that flexibility comes a few trade-offs. Spiral shielding doesn’t perform as well at high frequencies, and the spiral wrap can start to open up over time with repeated motion, which reduces its shielding effectiveness. It also tends to wear out more quickly under mechanical stress compared to more rigid options. Still, when flexibility and portability are top priority and the gear is always on the move, spiral shielding delivers the right mix of performance and agility.

Combination Shielding (Braid + Foil or More)

Multiple layers of shielding, commonly a foil shield for 100% coverage and a braided outer shield for low resistance and added strength. Some high-performance cables also include additional spiral shields or conductive tapes.

Key Properties:

-

Coverage: 100% (foil) + 70–95% (braid)

-

Flexibility: Moderate, depending on material choices

-

Flex Life: Higher than foil alone

-

Frequency Range: Effective across both low and high frequencies

-

Termination: More complex, but offers the best overall performance

Combination shielding is the all-in-one powerhouse, built like a tank and ready for the toughest jobs. It merges the strengths of foil and braided shielding to deliver unmatched protection across the full frequency spectrum.

You’ll find it in high-speed data lines like Cat6A and Cat7 Ethernet, harsh industrial settings, and sensitive medical or military-grade systems where failure is not an option. It’s the ultimate defense against EMI and RFI, offering both structural strength and signal clarity, even in the most demanding environments.

But with great power comes a bit of extra baggage. Combination shielding is heavier and more expensive than single-shield alternatives. Installation and termination can also be trickier and more time-consuming. Still, when the mission is critical and the environment is unforgiving, combination shielding stands its ground as it is rugged, reliable, and ready to perform.

Low Noise Coating

Low‑noise coating is a special conductive layer bonded to the insulation inside multi‑conductor cables, designed to combat microphonic or triboelectric noise. When cables bend, vibrate, or twist, friction between insulation and shield generates electrical charge, causing voltage spikes and signal degradation. The coating prevents those materials from charging by providing a dissipative pathway that shunts charge away immediately.

Unlike shielding, which blocks external EMI, low‑noise coating targets internally generated noise from cable motion. In sensitive systems, like medical sensors, test equipment, or audio, combining both greatly enhances signal clarity.

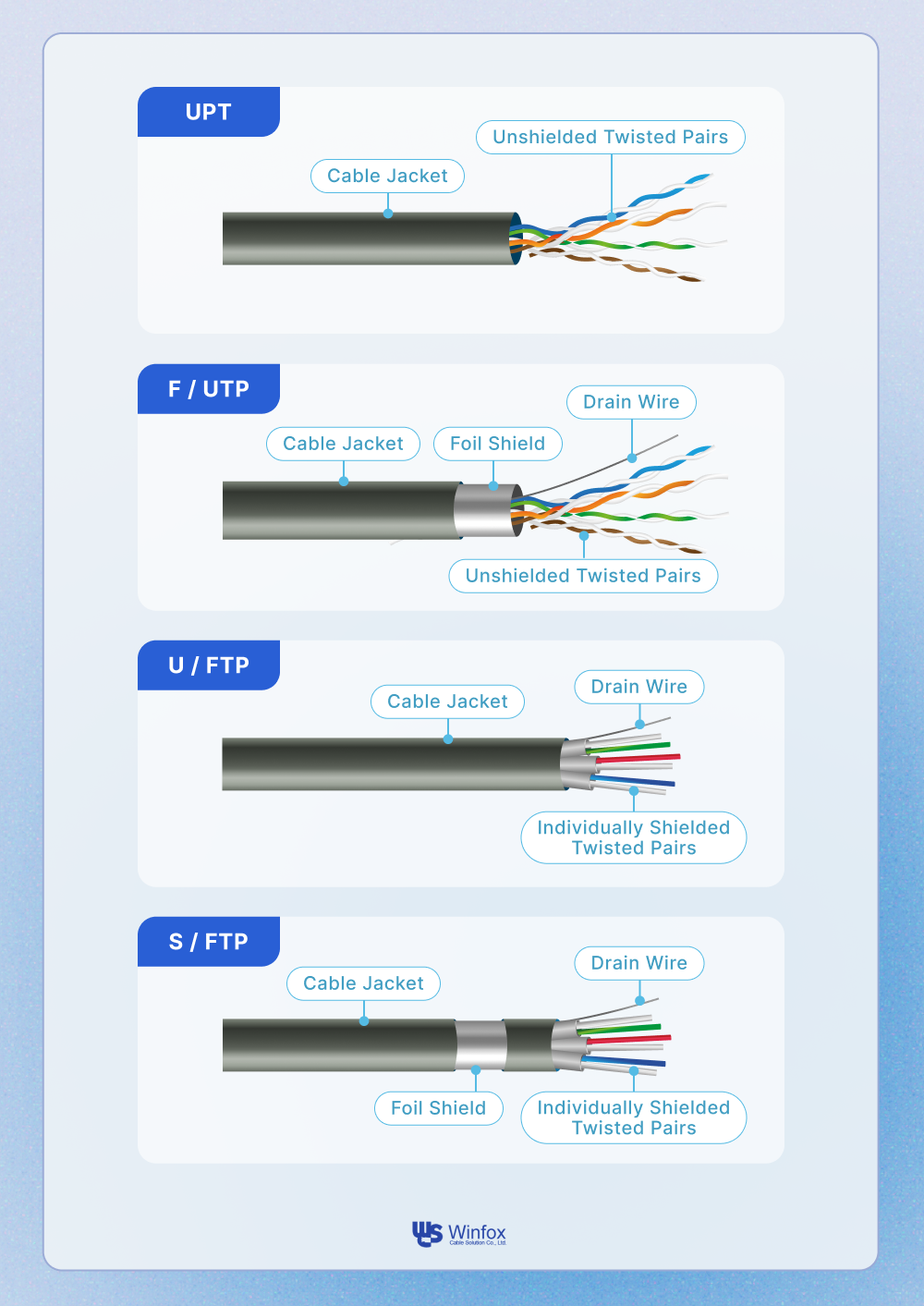

Shielding Codes and What They Mean

You’ll often see labels like UTP, FTP, or S/FTP on cable specs. These codes tell you what type of shielding the cable uses:

|

Code |

Meaning |

Shielding Structure |

|

UTP |

Unshielded Twisted Pair |

No shielding. Only twisted wire pairs inside. Common in homes and offices. |

|

F/UTP |

Foil over Unshielded Twisted Pair |

A foil shield wraps around all four wire pairs. Good EMI protection at a lower cost. |

|

S/UTP |

Braid over Unshielded Twisted Pair |

A braided shield around all wire pairs. Offers more strength and better low-frequency shielding. |

|

SF/UTP |

Foil + Braid over UTP |

Both foil and braid over unshielded pairs. Great all-around protection. |

|

F/FTP |

Foil on Each Pair + Overall Foil |

Each pair has foil shielding, plus another foil around all pairs. Strong high-frequency shielding. |

|

S/FTP |

Foil on Each Pair + Overall Braid |

Each pair has its own foil, and a braid covers the whole group. Maximum performance for EMI rejection. |

What is a Shielded Cable Used for?

Shielded cables are super important in a bunch of different places because they help keep signals clean and stop interference from messing things up. Here’s a quick rundown of shielded cable applications:

Data Centers

Data centers are full of servers, switches, and other electronic gear that generate a lot of EMI. This interference can scramble or degrade data signals, causing errors or slowdowns. Shielded cables help block this EMI so the network stays reliable and fast.

For example, cables with foil shielding protect against high-frequency interference, while braided shielding adds durability and blocks lower frequencies. Choosing the right shielding type can improve overall data integrity and reduce network problems, which is super important because data centers often run critical applications 24/7.

Medical Applications

Medical equipment, like ECG machines, imaging devices (MRI, X-ray), and diagnostic tools, needs extremely clean, accurate signals to work properly. EMI and radio frequency interference (RFI) can cause false readings or malfunctions, which could be dangerous. Shielded cables protect these devices by keeping interference out.

Plus, medical cables need to be durable and sometimes sterilizable, so the shielding and cable materials have to meet strict safety and hygiene standards. Many medical-grade shielded cables are designed with advanced insulation and biocompatible materials to ensure both safety and long-lasting performance.

Industrial Environments

Factories, manufacturing plants, and heavy processing facilities have tons of electrical noise from things like motors, transformers, welding machines, and power lines. This noise can cause signal degradation or even make machines malfunction, which might lead to downtime or safety hazards.

Shielded cables isolate the signals from all that noise, helping maintain smooth operation. In harsh industrial conditions, cables might also face heat, moisture, and physical wear, so the shielding also provides some protection against damage while keeping signals clean.

Commercial Settings

In offices, homes, and other commercial buildings, interference is usually less intense, so unshielded twisted pair cables often do the job. But if you have a lot of wireless devices like Wi-Fi routers, Bluetooth gadgets, or other sources of interference, shielded cables can add an extra layer of protection.

They’re also important if cables run long distances or pass through areas with more electrical noise, like near elevators or fluorescent lights, to avoid signal loss or interruptions. Plus, shielded cables help keep things running smoothly in places where consistent internet or data speeds matter, like in offices or streaming setups.

Defense

Military and defense applications require rock-solid reliability and security. EMI can be unpredictable in the battlefield or harsh environments, and any signal disruption could have serious consequences. Shielded cables are used extensively in military gear to protect communication lines, control systems, and sensitive electronics. They make sure signals aren’t corrupted by interference, keeping communications clear and equipment functioning properly. The cables also need to be tough enough to withstand extreme conditions like vibration, moisture, and temperature changes.

Winfox: Your Trusted Shielded Cables Manufacturer

At Winfox, we specialize in shielded signal cables and shielded electrical cables tailored for the most demanding medical environments. With over 30 years of experience, multiple patents, and ISO 9001:2015 and ISO 13485 certifications, we offer different types of cables that combine advanced insulation, superior shielding, and biocompatibility.

From ECG and dental equipment to complex multi-conductor and hybrid assemblies, our custom cable solutions are built for reliability, flexibility, and compliance with strict regulations. Get in touch with Winfox today and discover how our innovative shielded cable solutions can enhance your device’s performance, safety, and longevity.

Read More: