What is Parylene Coating: Process, Applications, Types, and More

Tired of coatings that crack, peel, or just don’t hold up? That’s a common frustration when dealing with delicate electronics or medical gear. Meet parylene conformal coating, the invisible armor that protects your components in even the harshest conditions. Follow us as we break down what it is, why it’s amazing, and where it works best.

What is Parylene Coating?

Parylene coating is a conformal coating, an ultra-thin polymer film that protects sensitive components by forming a uniform barrier across the entire surface. What sets it apart is how it's applied. Instead of being brushed or sprayed on like traditional coatings, parylene is deposited in vapor form through a process called Chemical Vapor Deposition (CVD).

The material’s origins trace back to the late 1940s at the University of Manchester, where it was first discovered. Later, William Gorham of Union Carbide developed the vapor deposition process that enabled commercial production. In 1968, CWST Para Tech Coating licensed this technology and introduced enhancements that improved performance, consistency, and reliability.

Because parylene is deposited molecule by molecule, it creates (or “grows”) a strong and invisible shield covering sheet edges, tiny holes, and complex shapes with a consistent thickness that helps protect electronics, medical tools, and other sensitive parts from damage. It's widely used in industries such as aerospace, healthcare, military, and consumer technology, where performance and reliability are crucial.

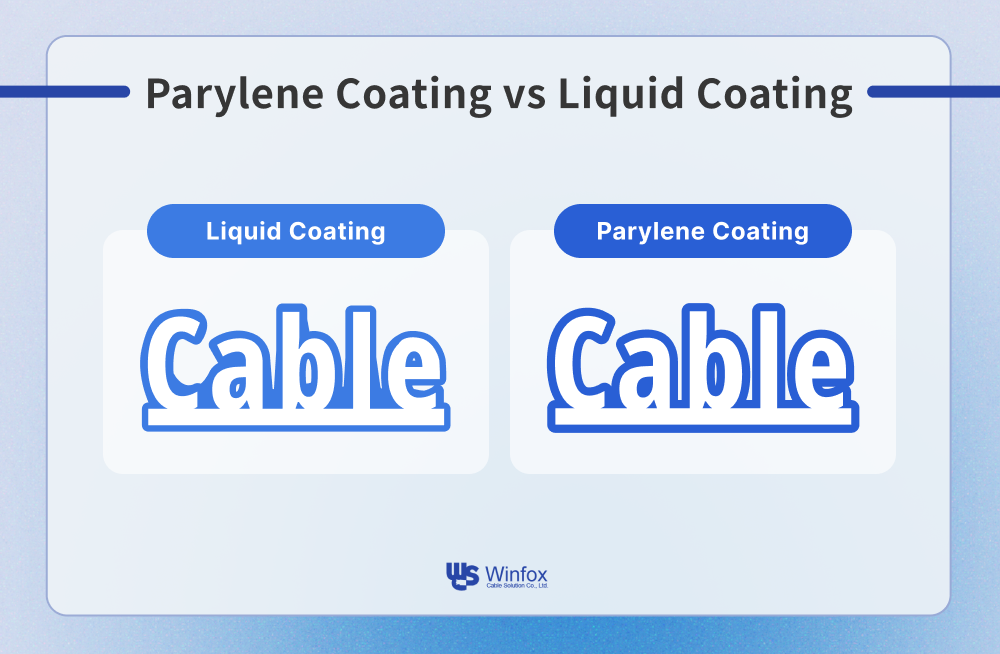

Parylene Coating vs Liquid Coating

Unlike traditional liquid coatings that are applied by spraying, brushing, or dipping, Parylene is applied in vapor form inside a vacuum chamber. This vapor-phase process allows the coating to form a thin, uniform layer over every surface, even sharp corners, deep crevices, and tight spaces that liquids often miss.

Liquid coatings tend to pool in low spots and pull away from edges, leading to uneven coverage. They can also develop bubbles, cracks, pinholes, or a rough “orange peel” finish, which weakens protection and appearance. These problems become more pronounced on complex parts or dense assemblies where liquid coatings struggle to reach hidden areas.

Parylene coatings, by contrast, deposit molecule by molecule, creating a smooth, pinhole-free, conformal film that wraps every contour evenly. Engineers can also precisely control thickness, from just a few hundred atoms to several microns, without affecting the part’s size, shape, or weight. The result is superior coverage, consistency, and protection unmatched by liquid coatings.

Benefits of Using Parylene Coating

Apart from its precise coverage and fully conformal barrier, this ultra-thin coating adds real value by protecting components from moisture, chemicals, corrosion, and wear. Here’s a simple breakdown of its key benefits:

Excellent Barrier Protection

Parylene creates a strong, invisible wall that keeps out things like moisture, chemicals, dust, and even corrosive gases. This makes it great for protecting devices that need to survive in tough environments, like inside the human body, in the ocean, or even outer space. For example, Parylene C is known to last over 10 years, shielding sensitive parts from water and chemicals without adding much weight.

Strong Electrical Insulation

Parylene is excellent at blocking electricity from leaking between parts. Even a very thin layer, with just a few microns, can handle high voltages. This is super useful for circuit boards and electronic devices where space is tight, and electrical safety is important. Parylene N, in particular, has outstanding dielectric properties, which means it insulates well without affecting how signals travel.

Built-In Lubrication

In thin layers, parylene has a slippery surface, similar to Teflon. This makes it useful for reducing friction in devices that move, like catheters in medical applications. It makes them easier to insert and remove without harming tissues, and unlike some lubricants, parylene won’t flake off or leave behind particles.

Safe for Medical Use

Parylene is biocompatible, which means it’s safe to use in or on the human body. It’s approved by the FDA and meets strict international safety standards like USP Class VI and ISO 10993. That’s why many implants and surgical tools are coated with parylene since it won’t react with body fluids or tissues, and it can survive repeated sterilization. Its smooth, non-tacky surface also resists dust and contaminants, making it ideal for high-cleanliness medical environments where hygiene and precision are critical.

Works on Many Materials

One of the best things about parylene is its versatility. It sticks well to all kinds of surfaces, including metal, plastic, rubber, glass, paper, and ceramic. That’s why you’ll find it used in everything from smartwatches to airplane parts, and from implantable medical devices to car sensors.

What is Parylene Coating Used for?

Parylene conformal coating is trusted across many industries because of its ability to protect delicate components in tough environments. It’s thin, strong, biocompatible, and highly resistant to chemicals, moisture, and heat. Let’s take a closer look at where parylene shines and why it’s such a trusted solution in these fields.

Medical Devices

Medical devices are a key area where parylene coating excels. With its FDA approval and proven biocompatibility, it’s widely used on implants, surgical tools, and diagnostic equipment. parylene forms an ultra-thin polymer nanofilm that resists solvents, drugs, and moisture, while also offering excellent barrier protection against oxidation and bacterial growth. It doesn’t react with body fluids, and it can handle repeated sterilization without breaking down. Moreover, it provides dry lubricity, which helps reduce friction in devices like catheters, guidewires, and needles, making procedures smoother and safer for patients. Whether it’s coating a pacemaker or a hearing aid, parylene keeps sensitive components safe and functional inside the human body.

Electronics

In the electronics industry, parylene is a game-changer for protecting circuit boards and electronic components. These devices are often packed into tight spaces and exposed to humidity, heat, dust, or corrosive elements. parylene coats every crevice and surface evenly, forming a watertight and chemical-resistant layer. It prevents corrosion, short circuits, and fungal growth while also reinforcing delicate solder joints and wire bonds. Because it doesn’t pool or bridge like liquid coatings, parylene is ideal for today’s compact, high-performance electronics that need protection without compromise.

Aerospace and Defense

In aerospace and defense, parylene’s durability and dependability are essential. Components used in satellites, drones, military vehicles, and avionics systems must operate under extreme conditions, from high altitudes and deep space to intense vibration and exposure to fuel vapors. Parylene provides an even, flexible coating that resists temperature swings, UV light, and corrosive gases. It protects everything from flight control sensors to navigation equipment, ensuring these systems stay functional and secure in the most demanding environments.

Industrial and Commercial Products

Parylene is also widely used in industrial and commercial products, especially when materials need a longer lifespan or added resistance to environmental wear. Since it can adhere to metals, plastics, rubber, glass, paper, and more, parylene is incredibly versatile. Manufacturers rely on it to improve the performance of filters, membranes, valves, and optical components. It offers a lightweight yet durable solution to protect parts from moisture, heat, or chemicals without interfering with performance or design.

Parylene Coating Process: Complete Steps

From inspection to masking, and all the way through vapor deposition, here’s a clear breakdown of the parylene conformal coating process.

Inspection

Before anything begins, parts go through an inspection step. This ensures they are clean, free of damage, and ready for coating. Checking at this stage helps catch any issues early and prevents wasting time or materials later. Inspections may happen again after each key step to ensure quality is maintained throughout the process.

Cleaning and Surface Preparation

Cleanliness is critical. Even tiny amounts of oil, dust, or fingerprints can prevent the coating from sticking properly. Parts are thoroughly cleaned using solvents, ultrasonic baths, or plasma treatment to remove all contaminants. For some surfaces, additional surface treatments are used to improve how well the coating sticks. This step sets the foundation for strong adhesion and a reliable coating.

Masking

Parylene coating covers everything it touches, like the surface, the crack, and the corner. But some areas might need to stay uncoated for the part to function properly. That’s where masking comes in. Special tapes, caps, or fixtures are used to block off these areas before coating. This step requires precision and careful handling to make sure only the right parts of the object are coated.

Adhesion Promotion (Recommended)

Although parylene naturally sticks to many materials, some surfaces, like polished metals or certain plastics, need a little help. Adhesion promotion steps improve how well the coating bonds to the part. Common methods include:

-

Silane Treatment (A-174): Parts are dipped in a liquid solution that chemically improves bonding.

-

Plasma Treatment: This high-energy gas treatment activates the surface to accept the coating better.

-

Surface Roughening: Gently scuffing the surface can help the coating hold on.

This step helps ensure the coating doesn’t peel or flake off during use.

Loading

Once the parts are cleaned, masked, and treated for adhesion, they are placed onto fixtures and carefully loaded into the vacuum chamber. These fixtures hold the parts securely and make sure every surface is exposed evenly during the coating process.

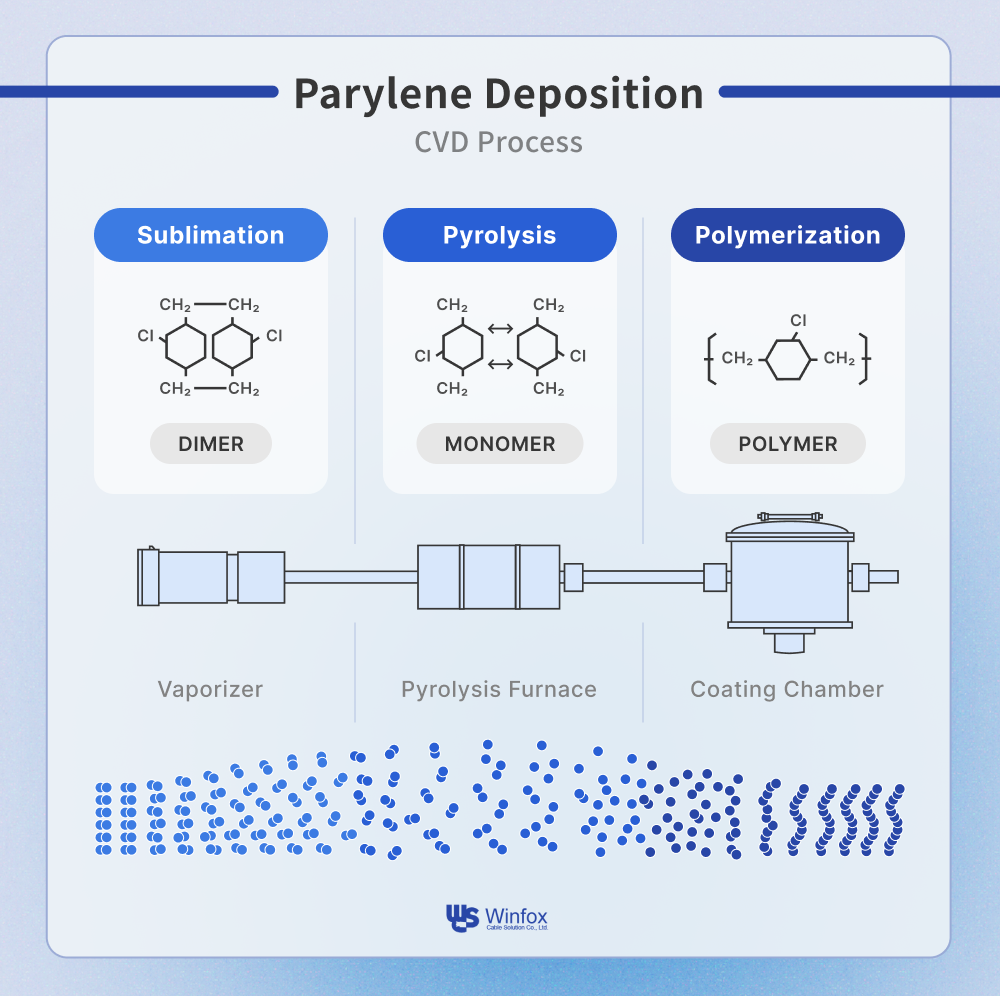

Parylene Deposition (CVD Process)

The actual coating is done using a special method called Chemical Vapor Deposition (CVD). This process happens in three key stages, all under vacuum and at room temperature:

Sublimation

First, the raw parylene material (called a dimer) is a solid powder. It’s heated to around 150°C inside the vacuum system. This turns the solid into a gas, a process called sublimation. The amount of dimer used helps control the final coating thickness.

Pyrolysis

Next, the gas flows into a very hot furnace, around 650°C, where it goes through pyrolysis. This step breaks the gas molecules into smaller, reactive units called monomers, which are ready to form the coating.

Polymerization

Finally, these monomer gases enter the deposition chamber, where the parts are waiting. Because the chamber is at room temperature, the gas molecules naturally stick to the surfaces and start bonding together, forming long polymer chains. This is polymerization. The coating grows evenly over every surface, one molecule at a time, creating a thin, pinhole-free, transparent layer.

Cooldown and Unloading

Once the coating is complete, the vacuum chamber is slowly returned to normal atmospheric pressure. The parts don’t need any extra cooling because the whole process happens at room temperature. Once the chamber is safe to open, the coated parts are removed from their fixtures, ready for final processing.

Demasking and Final Inspection

Any masking materials used earlier are now carefully removed. This step must be done with care to avoid damaging the new coating. Afterward, each part is inspected to check that the coating is the right thickness, properly covers the required areas, and adheres well. If everything checks out, the parts are labeled, packaged, and prepared for delivery.

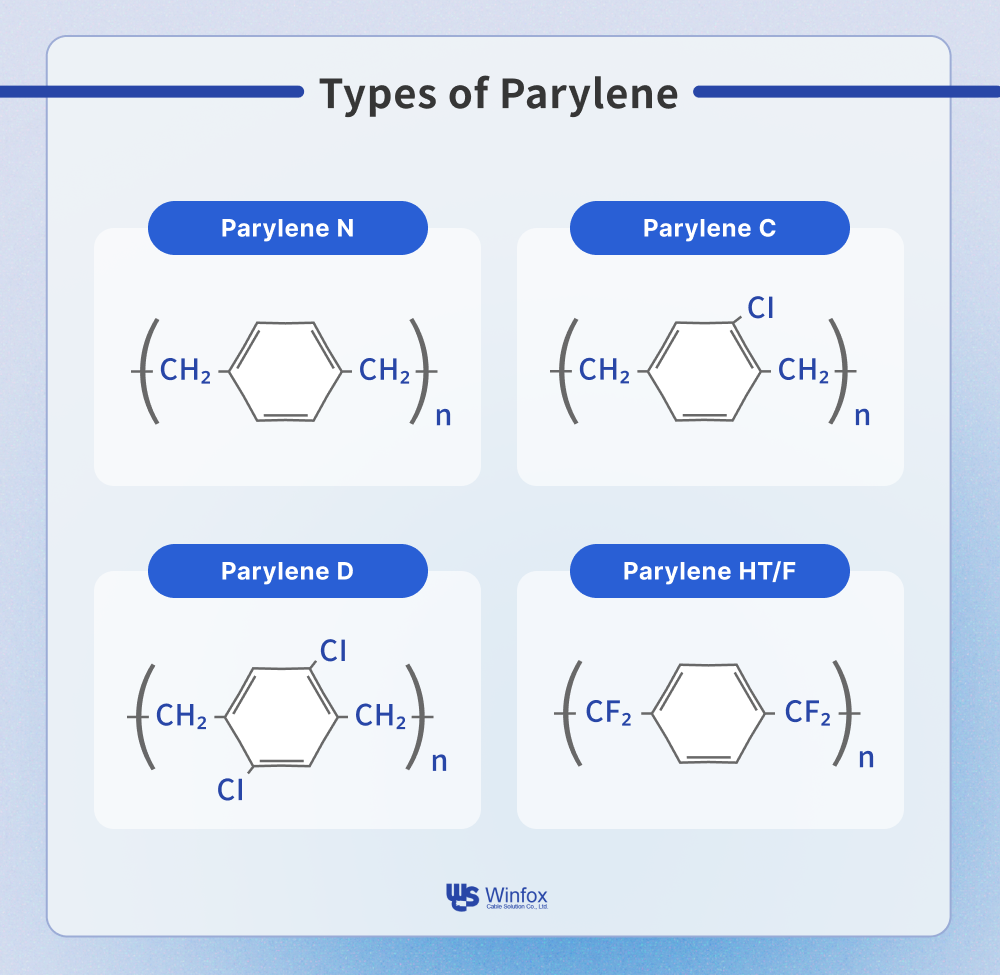

Types of Parylene

Parylene coatings come in several types, each tailored to meet specific performance needs across various industries. The four most common types, Parylene N, C, D, and HT (also known as Parylene F), offer distinct chemical structures and physical properties that make them suitable for different applications.

Parylene C Coating

Parylene C is the most widely used parylene type thanks to its balanced performance, cost-effectiveness, and chemical resistance. Its molecular structure includes a single chlorine atom, which enhances its ability to block moisture, corrosive gases, and solvents.

This makes Parylene C a go-to choice for protecting electronics and medical devices exposed to harsh environments. It also deposits faster than other parylenes, allowing for thicker coatings in less time, which improves processing efficiency.

Parylene C offers excellent protection in long-term applications, which can last over 10 years in severe conditions, and meets industry standards like MIL-I-46058C and IPC-CC-830. It is commonly used in implantable medical devices (such as pacemakers, defibrillators, stents, etc), and sensitive electronics.

Parylene N Coating

Parylene N is the original and foundational type in the parylene family, valued for its outstanding dielectric performance and ability to penetrate tight crevices. It offers excellent vacuum stability and a high melting point of 420°C.

One of its most notable traits is a very low dissipation factor and a dielectric constant that remains stable across frequencies, making it ideal for high-frequency or radio frequency applications. Its higher molecular activity allows it to penetrate complex shapes and tight spaces more effectively than other types.

Parylene N also provides dry lubricity, making it useful in applications that require smooth surface movement. This type is well-suited for electronics requiring precision electrical insulation and for components that need deep, even coverage.

Parylene D Coating

Parylene D shares similarities with Parylene C but offers higher thermal stability, making it better suited for applications that operate in elevated temperatures. It contains two chlorine atoms, which enhance its thermal resistance but slightly reduce its dielectric strength. It maintains electrical performance even in oxygen-rich, high-temperature environments, making it ideal for mission-critical assemblies.

Parylene D also features the highest tensile and yield strengths among the common types, though it is more brittle with a lower elongation at break. Due to these properties, it’s used less frequently but remains valuable for situations where heat resistance and mechanical strength are critical.

Parylene F Coating (Parylene HT Coating)

Parylene F, also called Parylene HT, is a fluorinated version of parylene designed for high-temperature and UV-stable environments. With four fluorine atoms in its chemical structure, it provides the best thermal resistance (up to 450°C), excellent UV durability, and the lowest coefficient of friction among all types.

Parylene HT is ideal for advanced medical devices and aerospace applications where components face continuous high heat or exposure to sunlight. It also maintains strong dielectric performance and deep crevice penetration. However, its slower deposition rate and higher material cost make it more suitable for specialized, high-value uses. Note that regulatory restrictions limit its use to medical and R&D applications.

|

Type |

Key Properties |

Best For |

Special Notes |

|

Parylene N |

High dielectric strength, low dissipation, deep penetration |

High-frequency electronics, RF systems |

Excellent electrical insulation, dry lubricity |

|

Parylene C |

Chemical resistance, fast deposition, durable barrier |

Medical implants, electronics, and harsh environments |

Most commonly used, cost-effective |

|

Parylene D |

High temperature resistance, strong mechanical strength |

Thermal and mission-critical assemblies |

Higher strength, lower dielectric strength |

|

Parylene HT/F |

UV resistance, high heat stability, and low friction |

Aerospace, high-temp medical devices |

Limited to medical and R&D use, slower deposition |

What Factors Affect the Cost of Parylene Coating

-

Coating Thickness: Thicker coatings require a longer time in the deposition chamber, which increases machine hours and overall cost. The optimal thickness depends on your application’s protection level and performance needs.

-

Masking Complexity: The more intricate your product design, the more masking and handling it requires. Complex masking increases labor time, raising processing costs.

-

Component Size: Larger components occupy more space in the vacuum chamber, reducing the number of parts coated per batch. This lowers batch efficiency and increases per-unit coating cost.

Disadvantages of Parylene Coating

While parylene coating offers outstanding protection and performance, there are a few practical considerations and limitations that users should be aware of. These are not necessarily disadvantages, but rather aspects of the process that can impact cost, time, and complexity.

One key factor is the thickness and time needed for deposition. Thicker parylene layers require longer chamber time, which extends the overall process duration. This can slow down production and increase costs, especially when compared to faster, traditional coating methods.

Batch size limitations are another concern. The deposition chamber has a fixed size, so only a limited number of parts can be coated at once. Larger components further reduce how many items fit in a batch, raising the per-part cost and reducing throughput.

Masking complexity adds to labor intensity. If certain areas must remain uncoated, careful masking is required before deposition and must be manually removed after, increasing operator time and effort.

Finally, adhesion and cleanliness are critical. Some materials require surface treatments to ensure proper bonding, and any contamination on the substrate can lead to coating failure. These strict requirements can make the process more demanding compared to simpler coating options.

Beyond Parylene Coating: Winfox Offers Medical Cables Engineered for Excellence

At Winfox, we focus on integrating parylene coating into our fine cable designs for medical use, since in clinical settings, every detail matters. Parylene’s advantages are clear: it offers outstanding biocompatibility, a smooth, low-friction surface that resists dust and contamination, and strong resistance to chemicals and sterilization agents. These properties make it ideal for protecting medical cables used in critical environments, ensuring reliability, hygiene, and long-term durability.

With over 30 years of experience, multiple patents, and certifications to ISO 9001:2015 and ISO 13485, Winfox manufactures a wide range of cables designed to meet rigorous quality requirements. Our offerings include custom-designed solutions featuring advanced insulation, superior shielding, and full biocompatibility, ready for your unique use.

Looking for a cable partner that understands the unique demands of medical innovation? Let’s create a solution that’s built for performance and ready for the next breakthrough. Contact us today to discuss your custom medical cable design needs!

Read More: