PRODUCTS

What is a multi-conductor cable? Also known as a multicore cable, it is a bundled cable that contains two or more insulated conductors within a single outer jacket. These cables are commonly used to simplify wiring, reduce clutter, and ensure efficient transmission of signals or electrical power. Whether it’s for data communication, control systems, or energy distribution, a multi-conductor cable offers a compact, organized solution for complex electrical setups.

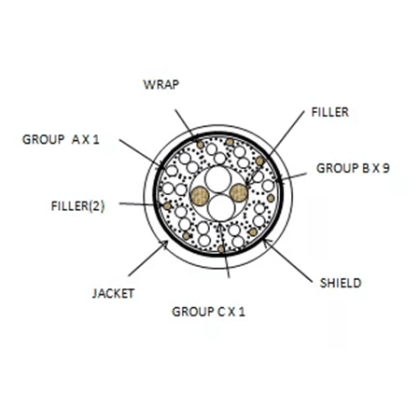

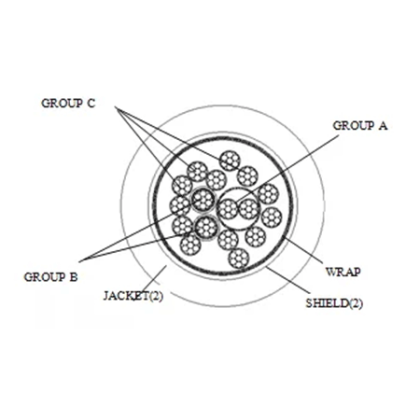

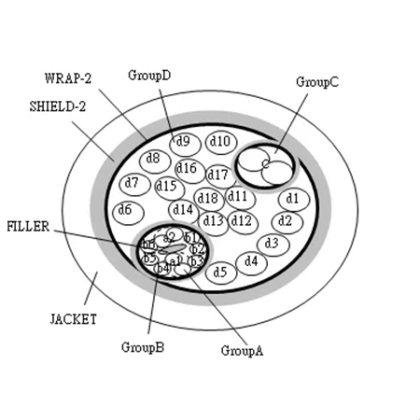

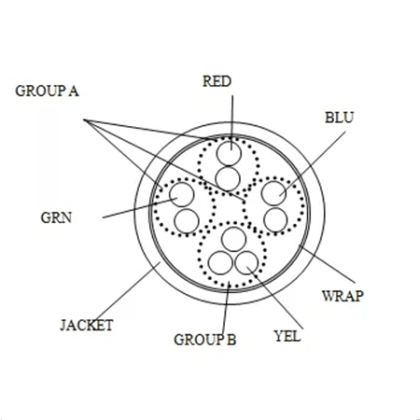

At Winfox, we specialize in designing and manufacturing custom multi-conductor power cables and electrical cables tailored to your exact specifications. From conductor count and insulation materials to different types of shielding and overall flexibility, our capabilities support a wide range of industries. What sets our cables apart is their proven resistance to harsh conditions as our builds can withstand chemicals, oil, extreme temperatures, flexing, and sterilization processes.

Looking for a high-performance multi-conductor cable built to last? Explore our full product range below or reach out to us to discuss your custom cable solution.

Our Multi-Conductor Cables Options

|

|

|

|

|

|

|

|

Why Choose Our Multi-Conductor Cables

|

|

True Customization with No MOQWe understand that off-the-shelf cables often fall short in specialized applications. That’s why we offer full customization: core count, conductor type, insulation, shielding, and jacket material, without imposing any minimum order quantity.

Whether you need a hybrid construction, micro-diameter build, or multi-core configuration, we deliver exactly what your application demands. |

|

|

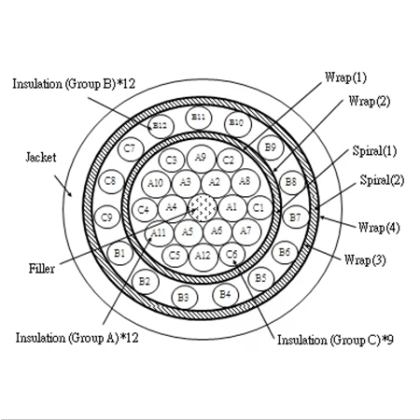

Precision Engineering for ConductorsFor high-density and precision applications, we produce ultra-fine conductors down to 50 AWG, with core diameters as small as 0.015 mm. Our designs support up to 60 conductor configurations, giving you maximum flexibility for complex systems.

We offer multi-strand constructions using premium materials such as copper alloys, silver-plated and nickel-plated copper, and thermocouple-grade wires, ideal for compact sensors, robotic mechanisms, and control circuits. |

|

|

High-Performance Insulation and Jacket TechnologiesWe offer a full spectrum of dielectric and mechanical insulation materials, including FEP, PFA, ETFE, TPE, TPU, silicone rubber (Shore 50A–80A), and low-smoke zero halogen (LSZH) compounds. The thinnest insulated cable we produce is just 0.05 mm in diameter, helping reduce bulk without compromising integrity, critical in medical, aerospace, and precision robotics. |

|

|

Advanced Shielding OptionsTo ensure signal integrity in high-noise environments, we integrate a wide range of shielding options in our cable design, including spiral wrap, braided wire (down to 50 AWG), aluminum Mylar, copper Mylar, and PTFE.

We can implement layered shielding for mission-critical systems, such as medical imaging, defense-grade controls, or high-frequency data transmission. |

|

|

Built for Harsh EnvironmentsDurability is in our DNA. We engineer cables to be bend-resistant, flame-retardant, abrasion-proof, oil- and chemical-resistant, and temperature-stable up to 280°C with materials like PVDF, ETFE, and PFA.

For dynamic applications, such as robotic arms, automated machinery, and coil cords, we ensure high flex life and mechanical reliability under constant motion. |

|

|

Certified for Global StandardsQuality and compliance are at the heart of Winfox’s manufacturing. We hold ISO (9001 & 13485) and UL certifications, and our medical cables are built to meet ISO10993, USP Class VI, and IEC60601 standards.

We also support UL and VDE-compliant cable builds for applications needing full adherence to safety and performance standards in regulated or mission-critical environments and deployments. |

Applications of Our Multi-Conductor Cables

Winfox Technologies specializes in the design and manufacturing of multi-conductor cables tailored for a diverse range of demanding applications. Our expertise ensures that each cable type meets specific industry standards and performance requirements.

-

Control and Instrumentation Systems: Designed for precise measurement and stability using K- or T-type copper conductors. Insulated with PVC, PU, Teflon, or silicone for reliable signal integrity in industrial environments.

-

Medical Applications: Built to meet ISO10993, USP Class VI, and IEC60601 standards. Our medical cables offer softness, flexibility, chemical and flame resistance, low smoke emission, and halogen-free safety for medical devices.

-

Robotic Systems and Automated Equipment: Feature high softness, wear and oil resistance, and withstand TIG, Tick bending, and Torsion Flex tests. Ideal for dynamic, repetitive-motion automation systems requiring durability and precision.

-

Audio and Acoustic Systems: Deliver clear analog or digital sound with excellent noise rejection. Made with flexible, rubber-like jackets and high tensile strength for professional audio and recording setups.

-

Communication and Data Transmission: Suitable for audiovisual, broadcast, and data systems. Provide customizable shielding, soft texture, and strong tensile strength for clear, stable signal performance.

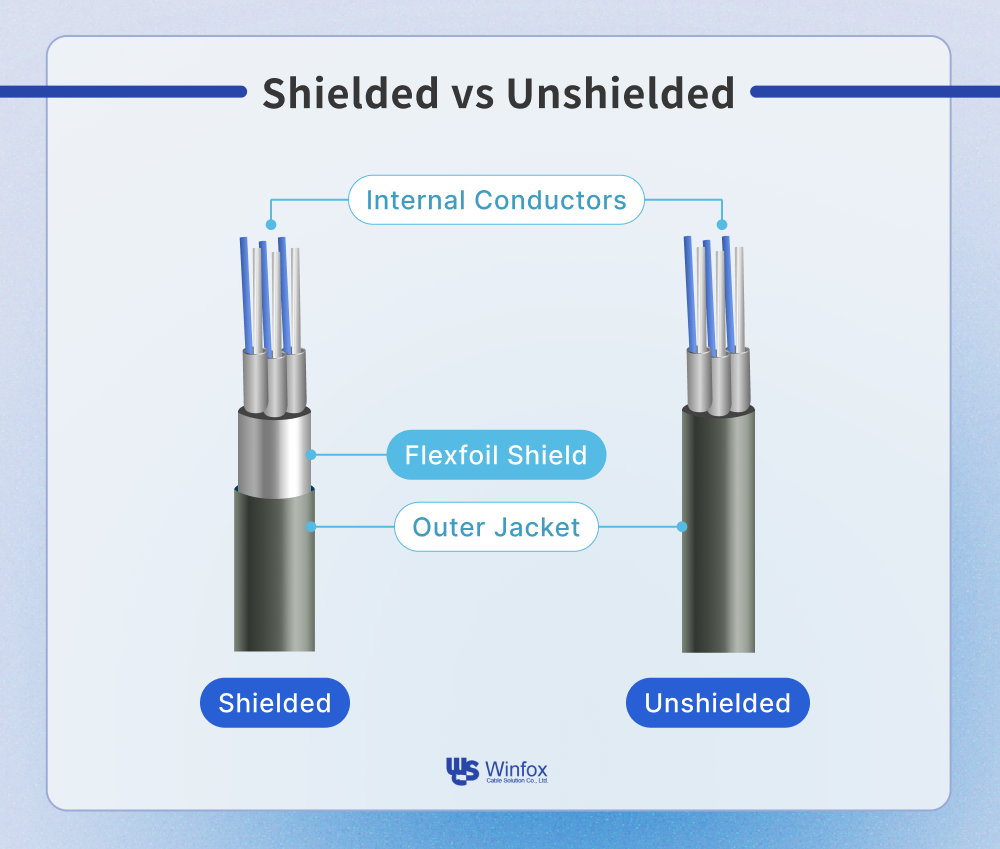

Differences Between Shielded and Unshielded Multi-conductor Cables

The main difference lies in signal protection, as shielded cables block electromagnetic interference (EMI), while unshielded cables do not.

Shielded multi-conductor cables use a metal layer (foil, braid, or both) around the conductors, along with a drain wire for grounding. This shield prevents interference from nearby motors, power lines, or electronic devices, keeping signals clean and stable. You’ll find them in industrial equipment, data centers, recording studios, and medical devices where reliability matters most. Though thicker, less flexible, and more costly, they’re essential in high-EMI environments.

Unshielded cables, often called UTP (Unshielded Twisted Pair), lack the metal shield, making them lighter, cheaper, and easier to install. They’re ideal for homes, offices, or short runs where electrical noise isn’t an issue. For example, standard Ethernet cables used in your router setup are typically unshielded. If the cable run is short and away from heavy electrical equipment, these are often all you need.

Different Types of Multi-Conductor Cables

When working with electronics, audio systems, or building wiring, you'll run into different types of multi-conductor cables. Let’s break down the most common types in simple terms:

-

Plenum Cable: Designed for air-handling spaces such as ceilings or raised floors. These cables use FEP or low-smoke PVC jackets that resist fire and emit very little smoke or toxic gas, making them essential for commercial buildings, schools, and hospitals where safety codes require plenum-rated materials.

-

Non-Plenum Cable: Used in general-purpose wiring through walls, floors, or raceways outside air-handling ducts. They’re made with PVC jackets and are more cost-effective than plenum cables. Subcategories include CM (general use), CMR (riser-rated for vertical spaces), and CMX (for outdoor or direct-burial use).

-

Fire Alarm Wire: Built for reliability during emergencies, these cables connect fire detection devices, alarms, and control panels. Ratings include FPL (general use), FPLR (riser-rated), and FPLP (plenum-rated). Some fire alarm cables are shielded to prevent interference, ensuring alarms function even under extreme conditions.

-

Speaker Wire: Designed to carry low-voltage audio signals from amplifiers to speakers. Usually a two-conductor setup, speaker wire focuses on low resistance for clean sound. 12 or 14 AWG is used for longer runs or higher power systems, while 16 AWG fits most home setups. Shielded versions are available for areas with electrical noise or commercial audio systems.

Single-Conductor vs Multi-Conductor Cable: Which to Choose

A single-conductor cable has one insulated wire, while a multi-conductor cable bundles two or more wires inside a shared jacket. Here’s how they compare:

-

Conductivity: Single conductors handle higher current with lower resistance, great for power delivery. Multi-conductors carry multiple signals or power feeds together, saving space.

-

Insulation: Both types have individual insulation, but multi-conductors add an outer sheath and optional shielding to reduce interference.

-

Installation: Single conductors are thin and flexible, but messy when used in large numbers. Multi-conductors simplify wiring by combining several lines in one cable.

-

Environment: Single conductors are easy to replace and customize for harsh spots. Multi-conductors offer better protection from vibration and bending.

-

Safety Compliance: Single conductors follow basic current and insulation standards. Multi-conductors meet wider requirements for shielding, fire resistance, and EMI control.

Single-conductor cables are best for simple circuits or high-power, long-distance runs where flexibility and easy replacement matter. Multi-conductor cables, on the other hand, keep wiring organized and shielded, making them ideal for control, audio, and data systems that require multiple signals with minimal interference.

FAQs

What gauges are available at Winfox?

Winfox offers conductor sizes down to 50 AWG, with core diameters as small as 0.015 mm. Larger gauges are also available for higher-power or signal applications.

How many conductors can you include in a cable?

Our multi-conductor cables can include up to 60 conductors in one jacket, allowing compact routing for control, signal, or power lines.

Which compliance standards does your multi-conductor cable adhere to?

Winfox cables meet ISO 9001, ISO 13485, UL, VDE, and medical-grade standards such as ISO 10993, USP Class VI, and IEC 60601.

What insulation, jacket, and shielding material options do you provide?

We offer materials like FEP, PFA, ETFE, TPU, TPE, silicone rubber, and LSZH. Shielding choices include braided wire, aluminium-Mylar, and copper-Mylar for EMI protection.

Do you require a minimum order quantity (MOQ), and how customizable are the cables?

There is no MOQ at Winfox. Each cable can be fully customized for conductor size, count, insulation, shielding, and jacket material.

What lead times and production capabilities should I expect for custom multi-conductor cables?

Lead times vary by specification, but Winfox provides full in-house design, prototyping, and production to ensure fast turnaround for custom orders.

In what kinds of applications and environments can your multi-conductor cables be used?

Our cables are suited for medical, robotics, automation, and industrial uses, designed to handle high flexibility, heat, oil, and chemical resistance up to 280 °C.

Tailored to Perform: Get Your Custom Multi-Conductor Cable from Winfox Today

With over 30 years of experience, multiple patents, and certifications to ISO 9001:2015 and ISO 13485, we at Winfox are committed to engineering different types of cables that exceed industry standards. Whether you need advanced insulation, multi-layer shielding, or full medical-grade biocompatibility, our custom multi-conductor cables are designed to deliver precision, durability, and compliance.

Please note that the product images on our website are intended to showcase design concepts. If you have specific requirements or technical questions, we welcome you to reach out directly. Let’s build a cable solution that’s engineered for performance and ready for your next innovation. Contact us today to get started on your custom multi-conductor cable.

Read More: